DuPont™ Tyvek® IsoClean®

Tyvek® IsoClean®IC 193 B WH TS

DuPont™ Tyvek® IsoClean® IC 193B TS. Robust yet lightweight protection providing an excellent barrier against fine particles and low-level sprays in a gamma-sterilized and aseptically folded white hooded coverall. Features bound internal seams, integrated overboots with a slip-resistant sole for enhanced slip-retardance, a medical mask fit five-piece hood with attached ties, tunnelled elastication at wrists, elasticated waist (stitched-in), elasticated thumb loops covered with Tyvek®, a pin lock slider zipper pull and a storm flap. Suitable for a variety of applications including cleanrooms in biotech, pharmaceutical, medical device manufacturing, food processing and cosmetics.Quantity/box: 20 per box, individually double packed. 2 polyethylene liners. Cardboard box.;20 per box, individually double packed. 2 polyethylene liners. Cardboard box.

Product Info & Wear Trials

Features:

DuPont™ Tyvek® IsoClean® hooded coverall, IC 193 B WH TS. Available in sizes XS to 7X. Gamma-sterilized. Bound internal seams. Integrated overboots with a slip retardant Gripper™ sole. The hood fits a medical mask and has attached ties. Elasticated waist at back for good fit. Tyvek® covered elasticated thumb loops. Tunnelled elastication at wrists. Front zipper closure. Storm flap.Tyvek® IsoClean® delivers an ideal balance of protection, durability and comfort. Made of high density polyethylene using a patented flash spinning process.Tyvek® IsoClean® provides an inherent barrier to particles, microorganisms and non-hazardous water-based light liquid splash. Tyvek® IsoClean® is also breathable and low linting.Tyvek® IsoClean® TS coveralls have been sterilized by gamma-irradiation. They are folded to aid aseptic donning and packaged in an ISO class 5 cleanroom. All DuPont™ Tyvek® IsoClean® sterile garments (option code TS) are packed in a dual barrier packaging system, consisting of an inner and outer easy tear cleanroom bag. The packaging system serves as a key element for contamination risk reduction when transferring apparel into clean areas.

Applications:

Garments and accessories made of sterile Tyvek® IsoClean® are typically used in cleanrooms within the hospital pharmacies, biotech, pharmaceutical, medical device manufacturing, food processing, cosmetics industry as well as in other critical or controlled environments.*Provided that the number and sizes of particles measured per m3 of air inside the cleanrooms stay within the limits defined by the GMP Annex 1, respectively the ISO 14644-1.

Benefits:

- Certified according to Regulation (EU) 2016/425.

- Hood and integrated boots

- Tyvek® IsoClean provides an inherent barrier to particles, microorganisms and non-hazardous water-based light liquid splash

- Tyvek® IsoClean is also breathable and low linting. Aseptically folded

- Clean-processed and sterilised by gamma-irradiation to SAL of 10-6 (ISO 11137-1)

- Full traceability on all sterilized apparel with Certificates of Sterility Available Here.

- Suitable for use in GMP class A/B (ISO Class 5) clean rooms.

- Chemical protective clothing, Category III, Type 5-B and 6-B..

- EN 14126 (barrier to infective agents), EN 1073-2 (protection against radioactive contamination).

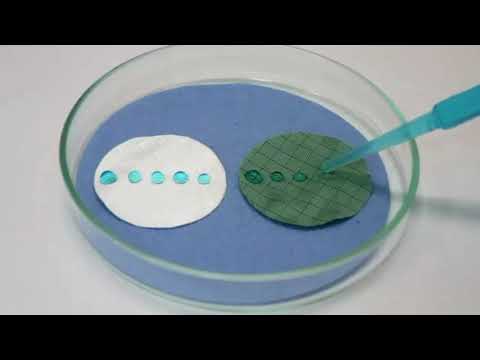

Protective suits may look the same, but only from a distance. Check out DuPont Tyvek® material advantages over Microporous Film and SMS

Permeation = a measure of chemical barrier performance. Permeation is invisible, but it may strike after a certain period of time if you are not sufficiently protected

Thanks to its unique structure, Tyvek® is a superior and safe barrier in terms of permeation resistance.

Microporous Film may give the perception of good liquid protection because of repellency properties when in reality chemicals quickly permeate through.

BEFORE & AFTER 10 CYCLES OF ABRASION: EN 530 – METHOD 2

Hydrostatic Head determines the resistance of a fabric to water penetration under slight pressure. A Hydrostatic Head of 100cm means that a fabric could hold a column of water that is 100cm tall.

Prior to the abrasion test Microporous Film offers the best resistance to liquid pressure. But after just 10 cycles of abrasion, its performance takes a spectacular dive, while SMS is less affected but starts from a much lower performance level, and Tyvek® continues to protect.

THE SUIT INWARD LEAKAGE TEST – EN ISO 13982 - 2

This test essentially determines the barrier efficiency of the suit when challenged with sodium chloride particulates of a defined size distribution.

Type 5 test allows up to 15% inward leakage of particulates in the suits but who wants to accept this hazardous particulate environment?

- Microporous film fabrics may be easily abraded and the barrier layer can be readily worn away.

- SMS fabrics tend to have quite open structures, offering low dry particle holdout performance to fine particulates.

- Tyvek® Classic Plus with over-taped seams offer a higher overall protection.

NOMINAL PROTECTION FACTOR - EN 1073-2

A suit which offers the highest protection to the fine particulates will have LOW inward leakage, and thus a HIGH nominal protection factor.

Tyvek® Labo and Tyvek® Classic Plus meet Class 2.

The nominal protection factor is between 50 and 500.

DRY LINTING PROPENSITY BS 6909

(method for generation and counting of the airborne linting propensity of fabrics in the dry state)

Tyvek® is the ideal material for application needing low linting (e.g: paint, pharmaceutical applications). By nature of its continuous strong high density polyethylene fibers it does not shed fibers.

Ret = the measurement of the resistance to evaporative heat loss. The lower the Ret value, the less resistance to moisture transfer and the more breathable the fabric.

SMS fabric with their open structure shows the best breathability performances but we know their protection performance is limited. Tyvek® offers the best balance between comfort and protection.

With their open structure, SMS coverall removes better the humidity than Microporous Film, by far.

Tyvek® meets quite good performances during sweating and recovery phase. Microporous Film is the material that takes the longest time to remove humidity.

When selecting a garment, carefully check the quality of the seams, as they contribute to the overall protection of the garment.

Not all seams are tight

Definition of tight = close

Tightness = so tightly made that liquids or gas cannot enter or escape.

Based on permeation and hydrohead test results, we can say that:

- Stitched seams are not fully tight

- Stitched and overtaped seam are tight and offer same barrier as fabric

PRODUCT STEWARDSHIP

All products must

- Be safe for use, correctly labeled to avoid misuse

- Meet performance marketing claims (supported by technical data)

- Composition verification for carcinogens and do not contain REACH substances or DMF

- Skin Patch (allergy) testing conducted, latex review by toxicologist

- Minimize environmental foot print

- Comply with legislation

HIGHEST ENVIRONMENTAL & ETHICS STANDARDS

Rigorous policies in place to ensure the highest environmental respect & ethical standards.

Health, safety, quality, environmental standards applied externally with converters that go well beyond the local requirements or legislation. Audits are made via LOCAL DuPont contract operations personnel.

TYVEK® STRINGENT QUALITY CONTROL SYSTEM

Tyvek® is routinely and rigorously controlled under strict procedures.

Tyvek® fabric production quality control monitors more than 200 data/day.

Tyvek® garments are controlled at the converter location and at DuPont.

TYVEK® QUALITY CONTROL COMPLIES WITH ARTICLE 11

DuPont has the experience and testing facilities to implement:

- “Non-routine” testing equipment for the fabric.

- Type 4 & 6 test cabin (calibrated and comparable with external institute).

DuPont is periodically audited by a notified body to check Tyvek® conformity to the relevant requirements.

- Coverall with attached hood and overboots

- Sterility Assurance Level (SAL) of 10-6 (ISO 11137)

- Dual barrier validated packaging system (option TS)

- Packed in an ISO Class 5 Certified Cleanroom.

- Internal bound seams covered with garment fabric to reinforce seam protection and reduce potential for liquid and particle penetration

- Suitable for use in GMP class A/B (ISO Class 5) clean rooms

- CE certified. Category III, Type 5-B and 6-B

- Full traceability with certificates of sterility